Business

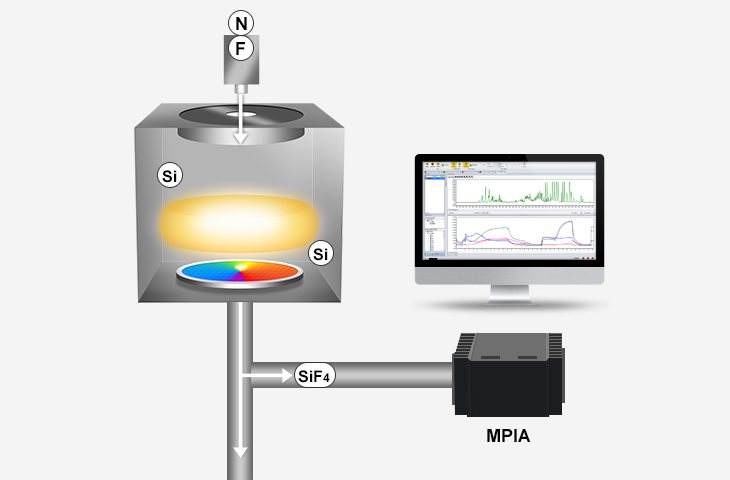

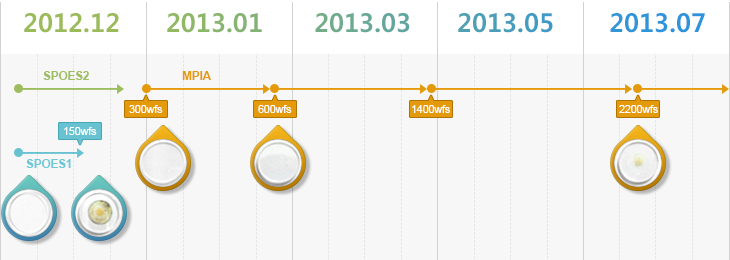

MPIA®(SPOES)

Superior stability, compact, high sensitivity

MPIA offers advanced anti contaminated features in a compact, lightweight that is easily installable, allowing for accurate and high sensitivity. MPIA is designed to unlock your process with SCM s/w frame for all of your gas analysis to help maximize yeilds and minimize tool downtime. As next smart sensor, it overcomes contamination issue of SPOES.

MPIA® Advantages

- Strong anti contamination

- The smallest size

- Strong plasma intensity

- High Sensitivity

- Simulation Function – Raw Data reprocess

MPIA® Applications

- Leak Detection

- Fault Detection

- Optimization of Cleaning/Seasoning time

- Abnormal Chemical Status (in Real Time)

- First wafer effect & Process Drift

Smart Sensor Operation SW (SCM™)

- Remote Control & Monitoring(Office Access)

- Interface with EQ or FAB FDC(Host)

- SW Flexibility for Adding Sensors

- Feed back to EQ in real time by Pre-defined cases

- Easy Way for Long Term data(DB)

- Various Analysis

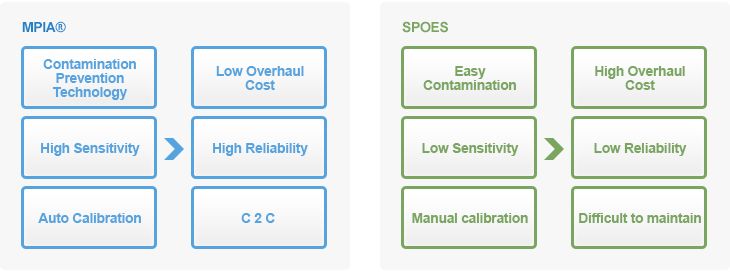

MPIA® VS SPOES Differences

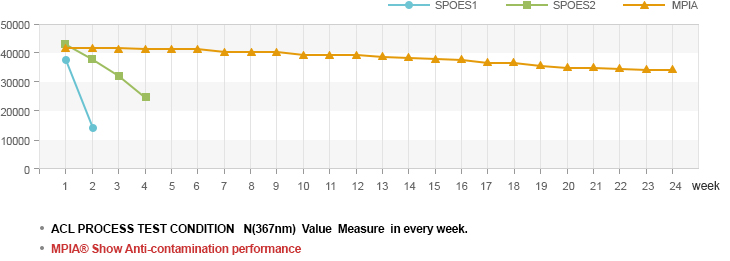

MPIA® & SPOES Contamination Test

MPIA® & SPOES Contamination

| Model | BitOn-5000 | BitOn-5000 | BitOn-5000 | BitOn-4500 BitOn-5000AD |

|---|---|---|---|---|

| Type | Normal | LP | HP | Discontinued |

| Operation Pressure | 5mTorr ~ 10mTorr | 1mTorr ~ 10Torr | 3Torr ~ 10Torr | |

| Application | TEOS ALD W Ti/TiN ACL SIO2 |

TEOS ALD W Ti/TiN ACL SIO2 |

TEOS ALD W Ti/TiN ACL SIO2 |

|

| Customer | Semiconductor & Display | |||

| Sale | On Sale | On Sale | On Sale | End of sales |

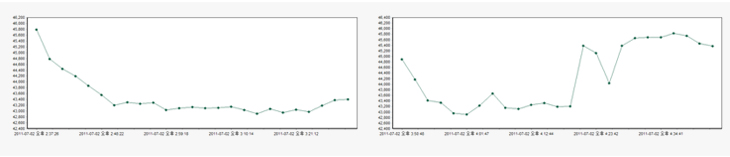

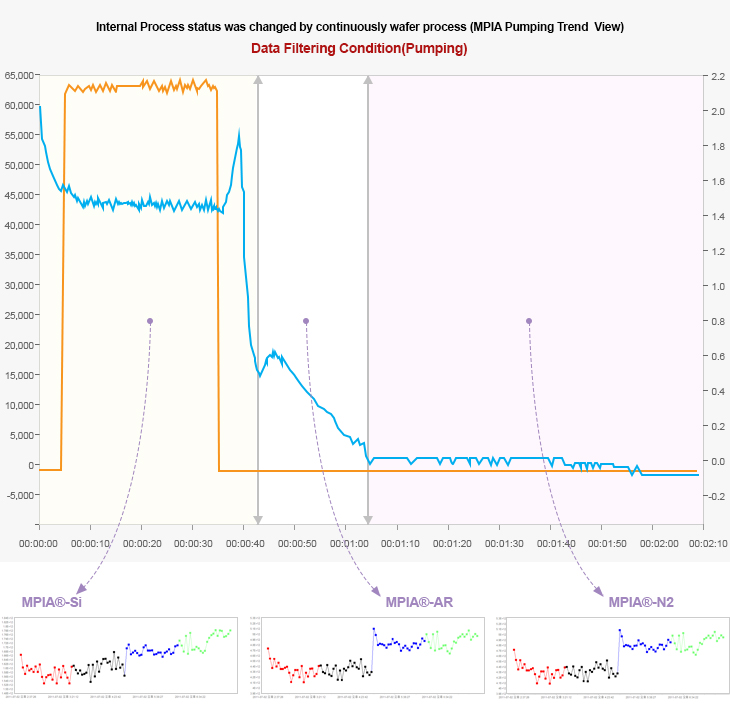

Pumping period (Fore Line GAS Build up Issue)

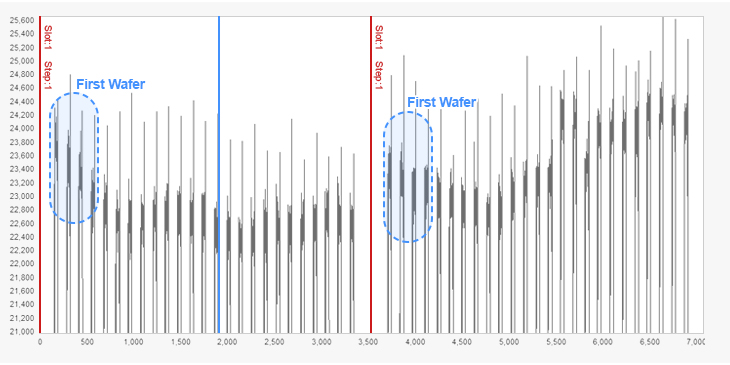

First Wafer Effect Detection & Continuous Process Lot trend

Lot wafer Summary - Process Step Trend (A Specific Wavelength)