Business

EPD

Reliable Optical Endpoint Detection Systems

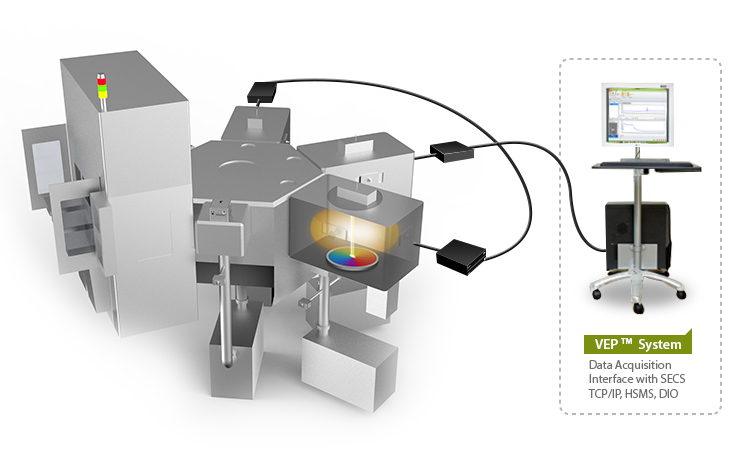

VEP™ Series are stable and well-defined s/w frame with various functions. We provide integrated solutions for epd, process chamber status ,film thickness measuement and cleanning optimization. We have three type products : VEP™-G&A / VEP™-Mono / VEP™-IEP

VEP™

To keep integrity of the stop layer and etch to a remaining amount of material, We need to know the endpoint. VEP™ was designed for detecting precise end point detection. Also we provide integrated solutions for gas chemistry changes through the optical emission.

Characteristics

- Trace the selected wavelength intensity

- End Point Detecting Function by pre-defined rule

- Optical Emission Spectra-scope Function

- Signal processing (Virtual data generation)

- Simulation Function – Raw Data reprocess

- Spectrum Libraries of Chemical Elements

- Advanced algorithm - PCA/HMM

- Plasma Triggered Process control

- Run info achieved by VEP™ own Interface or SECS/GEM & HSMS

- Customize EQ interface.

Classification

There are two types of VEP™ according to CCD : VEP™-Genearl & VEP™-Advanced

| General | Advanced | |

|---|---|---|

| Size | 162 X 140 X 70 | 215 X 184 X 142 |

| Resolution | (Slit/10um): 2.0nm | (Slit/10um): 2.0nm |

| Pixel | 2048 | 2048 |

| Wavelength | UV/VIS | UV/VIS |

| CCD Type | Normal Array CCD | Back-thinned CCD |

| Interface | LAN | LAN |

| Controller | Each Chamber | Each Chamber |

| Application | EPD | EPD |

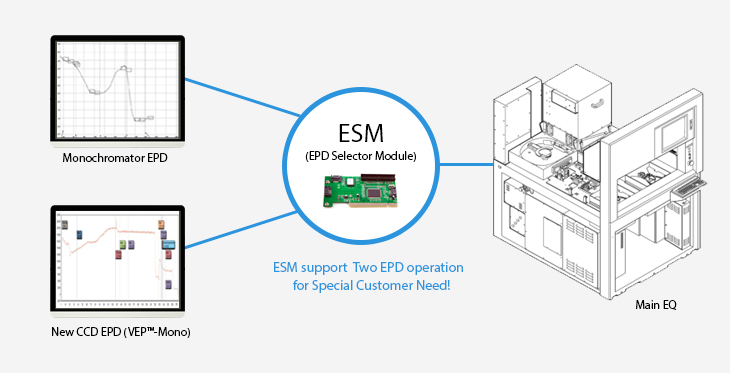

VEP™ - MONO

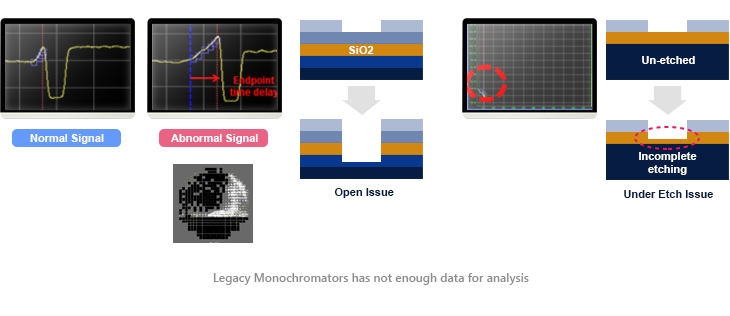

VEP-Mono is designed for replacing monochromator type epd called old epd system. Legacy Monochromators has several problems like general maintenance and data analysis. If you have a defect wafer and would like to know detailed main cause, it is difficult to analyze what the problem is.

Advantages

| ITEM | Monochrometer | VEP™-Mono |

|---|---|---|

| Chamber Down Time | Happen by EPD Fail | No |

| Defect Wafer | Happen by EPD Fail | No |

| Plasma Monitoring | Only specific wavelength | Full Wavelength |

| Analysis Tool | No | Yes |

| FDC co-relation | No | Support |

| System Performance | Old System | New System |

| Leak Detection | No | Yes |

| Mechanical Parts | Exist | No |

| Support (H/W & S/W) | Poor | Good |

| Maintenance | Need | No Need |

Characteristics

Flexibilities - Parallel Usage ESM allows operation the old Monochromator EPD and VEP™-Mono together

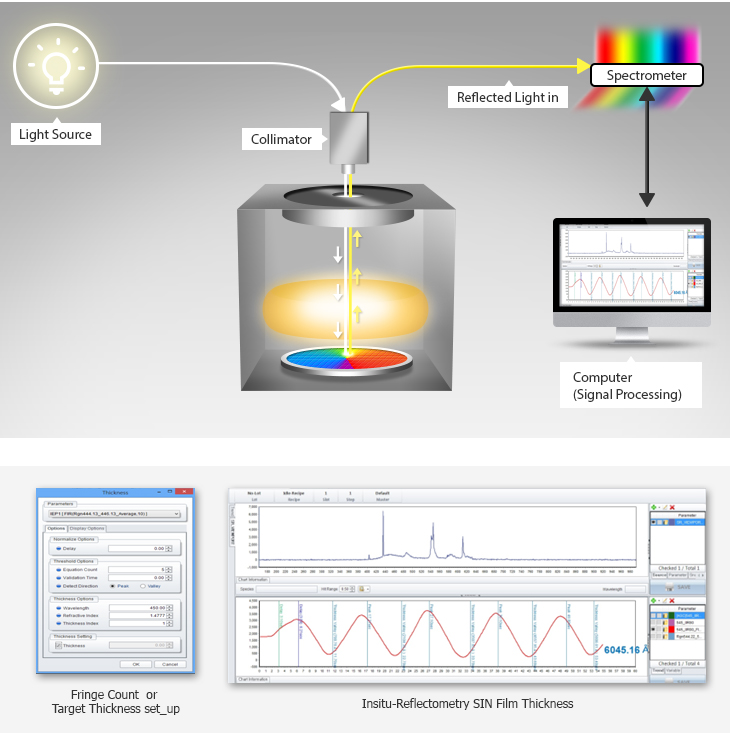

VEP™ - IEP (Insitu-Thickness Monitoring)

VEP™ IEP is designed for a wide variety of film thickness and depth measurement in real time required ETCH, CVD and CMP process. VEP™-IEP calculates the etching and coating speed of the monitored area by the interference intensity.