Business

Cirlex®

General Description

Cirlex® is an all-polyimide sheet material – has been developed to fill the growing requirement for thick all-polyimide materials, stemming from a wide variety of industries such as automotive, aerospace, and electronics. Cirlex® offers material flexibility and an expanded range of thickness options unattainable with cast resins or laminated constructions using adhesives. Also customers may use Cirlex® materials with Vespel applications. Offering the excellent chemical, physical, thermal and electrical properties of Kapton® in thick sheet format is unique in today’s material marketplace. You can count on Cirlex®’s integrity at extreme temperatures, from cryogenic [-269°C (-452°F)] to as high as 351°C (664°F); and it is readily modified/machined by laser cutting, drilling, machining and chemical etching.

Cirlex® Benefits

- Broaden your application horizons with 100% polyimide adhesiveless laminate

- Maintains all the excellent performance characteristics – electrical, physical and chemical – of DuPont™ Kapton®

- Available in thicknesses starting at 8mil (.008”,.20mm)

- Improved yields from large and custom sheet sizes

- Ideal match for environmental extremes

- UL® 94VO rated

Cirlex® Applications

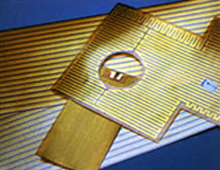

- Fine-Line Circuits

- High-Temp, Flexibile & Rigid Heaters

- Extreme Environment Antennas

- High Amperage Power Bus

- Solder Pad Stencils

- Flex Circuit Stiffeners

- Electrical Insulators

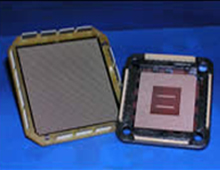

- Electromagnetic Wafer Chuc

- Fiber Optic Laser Guides

- Gaskets & Seals

- Wear Pads

- Stand-Offs & Spacers